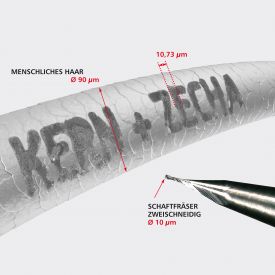

KLEINER GmbH and ZECHA: Trusted business partners for over 10 years

24-hour delivery: Made possible through regional proximity and a close, long-term partnershiph

With an impressive company history spanning more than three decades, KLEINER GmbH has established its name in the field of advanced stamping technology.