Milling of graphite and other hard-brittle non-ferrous materials presents a special challenge due to exceptional characteristics. Nevertheless, graphite material is an established element in tool and mould making, as well as in medical technology, and has become indispensable.

Specifically for the dry or wet machining of graphite, ZECHA Hartmetall-Werkzeugfabrikation GmbH has added an innovative series to the proven and patented1 line of SEAGULL® milling cutters.

In the machining of very thin-walled and intricate graphite shapes, excessive flute pressure frequently results in faulty contours, surface finishes, and dimensional accuracy. The ultra-stable ball nose end mills and end mills with corner radius with extremely short finishing flutes and a special geometry are ideally suited to handle the challenging requirements of electrode manufacture. The patented1, very short flute of the SEAGULL® milling cutters, in combination with a specially developed balance of carbide, diamond coating, and geometries, enables easy cutting in the milling of graphite and other hard-brittle non-ferrous materials in dry and wet machining. High-end milling cutters in the 567 and 577 series feature extremely tight tolerances. For maximum process reliability, each tool is measured before leaving ZECHA, and the actual dimensions are noted on the packaging label. The SEAGULL® quality milling cutters in the 568 and 578 series offer the solution for price-conscious users who still require high quality machining results.

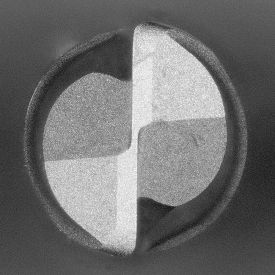

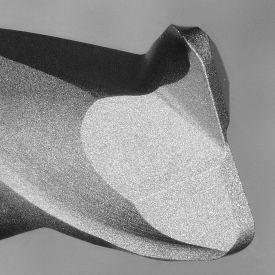

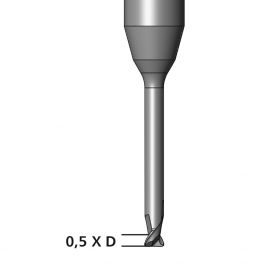

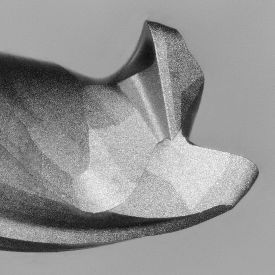

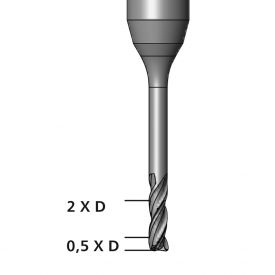

SEAGULL® 576.T3 – solid carbide end mill with corner radius with short finishing and long roughing flute

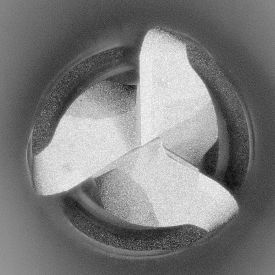

New in the SEAGULL® family is the 567.T3 end mill with corner radius produced by our own internal research and development department. With its three teeth, it is unique in the market and its combination of geometrical characteristics and flute dimensions creates generous chip space for material removal and high machining volumes during roughing, as well as the most intricate engagement conditions for finishing. In this way, flute pressure is reduced in the machining of narrow and deep contours for excellent surface finishes and long life cycles. The special geometry enables concentricities of 0.003 mm and diameter tolerances of

- 0/0.010 mm with a diameter of less than 6.0 mm and a length of less than 70 mm. The unique 1 long flute run-out with a variety of new corner radii achieves material removal also in deep contours and presents the right tool for every electrode dimension.

The innovative SEAGULL® milling cutters with their refined geometries offer new options in the dry and wet machining of graphite and other hard-brittle non-ferrous materials. New insights and future developments will surely not be long in coming.

Figure 1: SEAGULL® 576.T3 - Figure 2: SEAGULL® 576.T3 and 577 / 578

Series 567/568 & 577/578 Short finishing flute

Series 576.T3 Short finishing and long roughing flute

1 SEAGULL® products are protected by one or more of the following patents EP 2540427B1 in the following countries: DE, AT, CH, CZ, LIE, FR, GB, IT, NL, PL, PT, TR

ZECHA Hartmetall-Werkzeugfabrikation GmbH

ZECHA Hartmetall-Werkzeugfabrikation GmbH has been a pioneer and trendsetter in the field of micro cutting, blanking and forming tools for almost 60 years. The company can trace its origins back to the chronograph industry – which probably explains the uncompromising commitment to manufacturing not only miniature tools of the highest precision but also customized tool solutions.

Precision and quality are key features for international application in different industries, such as medical and dental technology, chronograph or automotive industry or in the mould making field. Experts in the company’s own technology department are constantly developing, also in collaboration with universities, groundbreaking geometries and tools for sophisticated applications and cutting-edge materials.

In addition, tool reproducibility is also guaranteed even for years by an identification number engraved on the end of the shaft of every tool.

Modern CNC machines, high-end measuring and testing technologies, and carefully selected hard metals of leading manufacturers, as well as an intensive cooperation with our customers and partners, ensure the exceptional perfection of our tools.

For more information:

ZECHA Hartmetall- Werkzeugfabrikation GmbH

Benzstraße 2

75203 Königsbach-Stein

Tel: +49 (0)7232 3022-0

यह ईमेल पता spambots से संरक्षित किया जा रहा है. आप जावास्क्रिप्ट यह देखने के सक्षम होना चाहिए.

www.zecha.de

Editorial offices please note:

Text and photos can be requested as files from ZECHA

Tel: +49 (0)7232 3022-0

यह ईमेल पता spambots से संरक्षित किया जा रहा है. आप जावास्क्रिप्ट यह देखने के सक्षम होना चाहिए.