The precision requirements made on tools rise almost on a daily basis – the need is for even higher tool service lives, even higher precision and even better surface qualities.

However, one thing is also clear: more exotic tools are being called for. Two experts, ZECHA Hartmetall-Werkzeugfabrikation GmbH and the machine manufacturer KERN Microtechnik GmbH, have come together to breathe life into their passion for maximum precision:

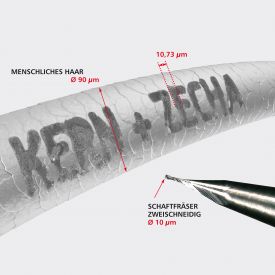

How do we define precision and how far can it be taken? The proof – a logo milled into a human hair – provides the final answer: very far indeed!

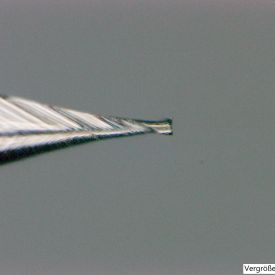

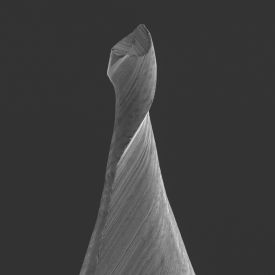

The fascination is great. Difficult to imagine that a hair can be lettered using a mill cutter. Everybody knows how fine hair is, so how microscopically small must the mill cutter be to achieve the feat? Yet, ZECHA and KERN have turned the unimaginable into reality and lettered a human hair with a diameter of 90 µm using a dual blade ZECHA mill cutter. As a specialist in micro machining, stamping and shaping tools,

ZECHA has produced and developed high quality and precision tool solutions for a vast range of sectors and applications for almost 60 years. The specially developed carbide shaft mill cutter employed has two cutting edges and with a diameter of a mere 10 µm work extremely finely and precisely. The tool and machine combination, here the KERN Micro HD, operating at a spindle speed of up to 50,000 rpm and a feed rate per tooth of 1 µm, achieve the unbelievable lettering width of 10.73 µm. Results that can only be appreciated under a scanning electron microscope.

Even if the lettering of a human hair does not turn out to be a requirement in the future, it does show us the dimensions of precision that can be achieved in micro machining. The high quality and accuracy in each individual application can only be achieved by the ideal combination of tool, machine and use

Kern Microtechnik GmbH

KERN Microtechnik GmbH based in Eschenlohe, has a workforce of around 200 employees and operates successfully in more than 30 countries. The company focuses on two business fields: the development and manufacture of highly precise processing centres and the manufacture of minute micro-milled parts for customers.

For more information:

KERN Microtechnik GmbH

Irma Gschmeißner

Olympiastraße 2

D-82438 Eschenlohe

Tel.: +49 (0)88 24 / 91 01-0

Fax: +49 (0)88 24 / 91 01-124

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.kern-microtechnik.com

ZECHA Hartmetall-Werkzeugfabrikation GmbH

ZECHA Hartmetall-Werkzeugfabrikation GmbH has been one of the pioneers and trendsetters in the field of micromachining, stamping and shaping tools for almost 60 years. Tracing its roots back to the chronological industry, the company has focused uncompromisingly on miniature tools of the highest precision, as demonstrated not only by its extensive range of stock products, but also by its special solutions.

Precision and quality are essential for international deployment in different sectors such as, for example, in the medical and dental technology, automotive or in tool and moulding construction. Experts at our own research and development department work continuously to develop cutting-edge geometries and tools for exotic applications and ultramodern materials.

In addition, the life number engraved at the end of the shaft of each and every tool also assures reproducibility of the tools well into the future.

A modern CNC machine park, high-end measuring and testing technologies and carefully selected carbides drawn from leading manufacturers as well as a close collaboration with our customers and partners guarantee the extraordinary perfection of our tools.

For more information:

ZECHA Hartmetall- Werkzeugfabrikation GmbH

Benzstraße 2

75203 Königsbach-Stein

Tel: +49 (0)7232 3022-0

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.zecha.de

Editorial offices please note:

Text and photos can be requested as files from ZECHA

Tel: +49 (0)7232 3022-0

This email address is being protected from spambots. You need JavaScript enabled to view it.