ZECHA Hartmetall-Werkzeugfabrikation GmbH has always been involved in the development of micro-precision tools of the highest level. The high-end mill cutter line IGUANA sees it making an evolutionary step in the diamond coated hard metal tool segment.

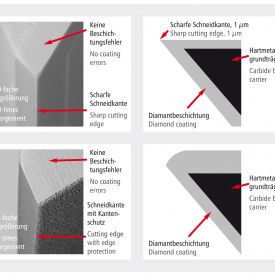

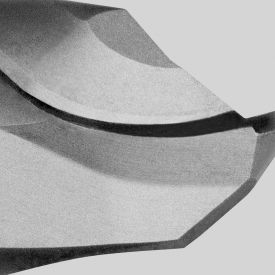

The three existing series in the IGUANA line are now being supplemented by three new lines - series 903, 913 and 916 with edge protection. These new high-end mill cutters with laser-sharp cutting edges are also furnished with a sealed high-performance diamond coating. However, the fact that they are only sharpened on one side provides special edge protection and reinforced cutting geometry.

On the previous IGUANA series 902, 912 and 915, the specific processing of the cutting edges by means of laser technology (R=1µ) and the special cutting geometry led to a considerable reduction in cutting forces.

This resulted in a lower machining temperature and in turn the tools achieved higher life cycles and tool lives. An additional advantage of the laser process is the clusterless tool flutes, which produce an improved surface quality in comparison to conventional diamond coated tools.

The IGUANA mill cutters from ZECHA master the machining of non-ferrous metals such as copper or high-performance copper alloys with ease.

Meeting the challenge of PEEK machining

The new stabilised edge high-end mill cutters from ZECHA are well up to the challenges of PEEK machining. This highly abrasive material leads to quicker wear of all standard tools and as a result of the cutting edge wear generates high friction heat.

This leads to poorer surface quality of the components and increased burring. ZECHA sees the use of the IGUANA mill cutters as one way of solving the problem.

The optimised geometry improves cutting performance and chip removal. Virtually no tool wear can be detected, and thus the tool service life is considerably lengthened. There is also no additional reworking due to burring required. The option of either wet or dry machining is another advantage of the mill cutter line.

Conclusion:

The IGUANA mill cutter series, which boasts a sealed diamond coating despite sharpened cutting edge, offers enormous potential for process optimisation, does away with uneconomical reworking stages and also improves the entire economic efficiency thanks to the prolonged service life and the resulting lower tool change necessity.

What's next? – Helix!

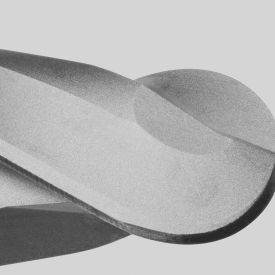

The areas of application of this novel tool technology are yet to be fully exhausted. New findings paired with special adaptations means that ZECHA has now managed to integrate a helix in the manufacture of the IGUANA series.

The almost freely selectable spiralisation of the tools promises great improvements in further areas of use. Materials difficult to machine such as medical (fibre-reinforced) plastics or lead-free brass alloys can be ideally machined thanks to the positive helix characteristics - softer cut, rounded groove forms, chip removal etc. Typical challenges such as precision, life cycles and manual reworking are efficiently mastered.

The helix fluted IGUANA tools will now be available not only as ball, torus and shaft mill cutters but also and for the first time as a spiral drill.

Figure 1: IGUANA – diamond coated, laser-processed tools with sharp cutting edge

Figure 2 + 3: IGUANA – laser-processed tools with edge protection and integrated helix

Figure 4: IGUANA ball, torus and shaft mill cutters as well as laser-processed sharp cutting edge

For more information:

ZECHA Hartmetall- Werkzeugfabrikation GmbH

Benzstraße 2

75203 Königsbach-Stein

Tel: +49 (0)7232 3022-0

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.zecha.de

Editorial offices please note:

ZECHA can provide the text and photos as a data file on request

Tel: +49 (0)7232 3022-0

This email address is being protected from spambots. You need JavaScript enabled to view it.