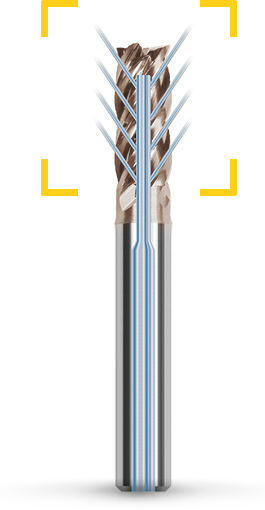

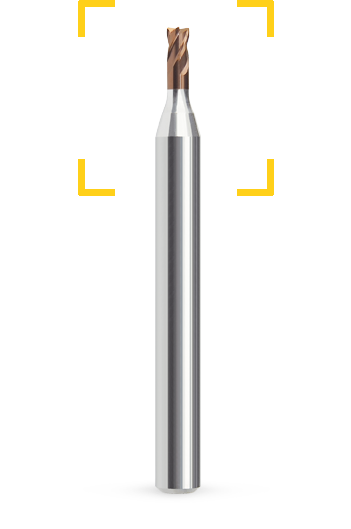

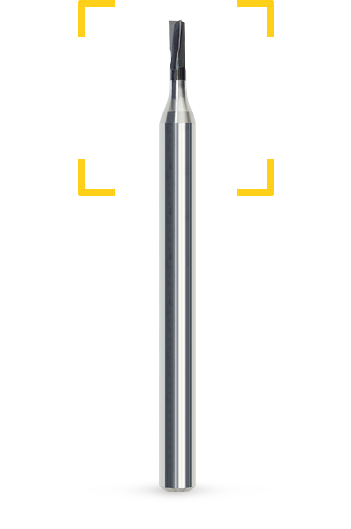

Now discover the difference of the IGUANA tool used before and after the live milling event. As a basis for comparison for the subsequent measurement results, the mold was already measured in detail in advance: on the left, the results of the IGUANA cutter at a runtime of 0 hours and on the right the comparison after incredible 641 hours and a covered milling path of more than 27 kilometers.

After tool use, the tool shows neither wear nor a relevant change in shape. The surface measurements reflect the programmed roughness of Ra 0.25 within the measurement and manufacturing tolerance. Based on the surface optics, it can be seen that the traverse paths of the machine are very accurate. Despite the tool size (Ø 1 mm), the contour was machined very precisely and without burr formation at the contour transitions, which additionally speaks for the repeatability of the machine/tooling combination.

IGUANA milling cutters are manufactured to a tolerance of < 0.002 mm. Although the IGUANA milling cutter used has a minimal form deviation in the center due to the manufacturing process, it is within the tolerance range both before and after the event and therefore does not show any wear whatsoever.

Further measurement results can be found in the booklet.